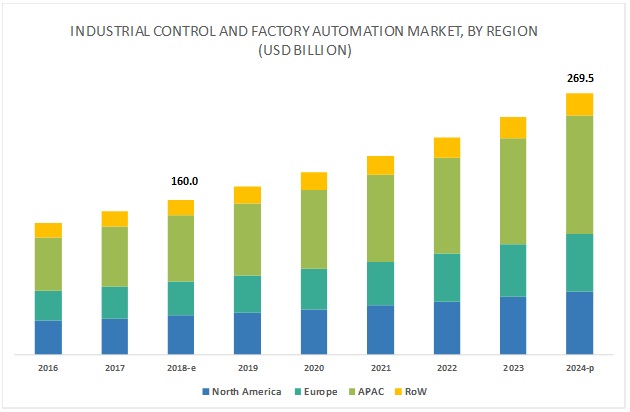

New market research report "Industrial Control and Factory Automation Market by Solution (SCADA, PLC, DCS, MES, PLM, PAM, Functional Safety), Component (Industrial Robots, Industrial 3D Printing, Control Valves, Machine Vision, HMI), Industry and Geography - Global Forecast to 2024", The industrial control and factory automation market is likely to reach USD 269.5 billion by 2024 from USD 160.0 billion in 2018, at a CAGR of 9.08%.

About : Industrial Control and Factory Automation Market

The growth of this market can be attributed to the increasing use of enabling technologies in manufacturing, rising adoption of industrial robots in manufacturing sector, connected supply chain along with mass production to cater rising population, government initiatives towards, the adoption of industrial automation in various industries.

• Request Sample Pages of Report :-

Major Players operating in the industrial control and factory automation market Emerson (US), ABB (Switzerland), Siemens (Germany), General Electric (US), Schneider (France), Endress+Hauser (Switzerland), Yokogawa (Japan), Honeywell (US), WIKA (Germany), Azbil (Japan), Fuji Electric (Japan), 3D Systems (US), HP (US), FANUC (Japan), STRATASYS (US), Progea (Italy), Hitachi (Japan), Vega (Germany), Danfoss (Denmark), Tegan Innovations (Ireland), Krohne (Germany), Rockwell (US), Chaos Prime (US) and Dwyer (US), among many others.

Browse 119 market data Tables and 48 Figures spread through 222 Pages and in-depth TOC on "Industrial Control and Factory Automation Market"

“Articulated robots dominate the industrial robot market”

“Articulated robots dominate the industrial robot market”

The industrial robots segment is growing at a significant pace during the forecast period and has the highest market share of components in the industrial control and factory automation market. Manufacturers are installing industrial robots to make production and distribution easy and efficient. The installation of industrial robots is lessening the human intervention in production process, thereby reducing the cost of manufacturing with increase in quality and production capacity.

“Process automation and control in industrial manufacturing plant drives the growth for DCS ”

DCS held the highest market share in the solutions of industry control and factory automation market. This growth is attributed to a high rate of industrialization rate in the developing economies. Developing countries have expansion and capacity addition plans related to the power sector, which would boost the demand for DCS. DCS provides process automation and control in industrial manufacturing plants that drive the industrial control and factory automation market. Advantages of using DCS systems in manufacturing plants are decision integrity, simplified operations, and increasing productivity. Some of the application areas of DCS are oil & gas, automobile, chemical, food & beverages, and pharmaceuticals industries.

“Process industries to lead the industrial control and factory automation market from 2018 to 2024”

Process industries had the higher market share in industry control and factory automation market in 2017. The rate of adoption of solutions related to the industrial control and factory automation is high in process industries owing to rising cost pressure on manufacturers to optimize the production process. Furthermore, increasing demand for real-time visibility and complex operations in oil and gas, power, metals and mining, and food & beverages industries is expected to drive the demand for industrial control and factory automation solutions in the process industry. Due to the complex nature of the automation in the process industry, the number of components and technologies deployed in the process industry is higher than the discrete industry. Particularly, control technologies, such as DCS, is employed only in the process industry and the number of PLCs and PACs is employed more in the process industry than the discrete industry.

“APAC to be the largest market for industry control and factory automation during the forecast period”

Asia Pacific (APAC) comprises Japan, China, India, and RoAPAC. APAC is the fastest growing region for industrial control and factory automation market due to the technological innovation and increasing adoption of the automation technologies in various industries. The major application industries for the industrial control and factory automation market in APAC are chemicals, oil & gas, water, semiconductor, electronics, food, and automotive. China is one of the major players from APAC region in the industry control and factory automation market. China has been working on an innovative industrial practice by implementing automation technologies in manufacturing. In addition, research institutes and corporates are collaboratively working to improve the Chinas manufacturing processes. Further, in China, industrial intellectualization and information integration remain the main focus of the government industrial policy. This initiative is expected to increase the demand for the industrial control and factory automation in this country.

About MarketsandMarkets™

About MarketsandMarkets™

MarketsandMarkets™ provides quantified B2B research on 30,000 high growth niche opportunities/threats which will impact 70% to 80% of worldwide companies’ revenues. Currently servicing 7500 customers worldwide including 80% of global Fortune 1000 companies as clients. Almost 75,000 top officers across eight industries worldwide approach MarketsandMarkets™ for their painpoints around revenues decisions.

Contact:

Mr. Shelly Singh

MarketsandMarkets™ INC.

630 Dundee Road

Suite 430

Northbrook, IL 60062

USA : 1-888-600-6441

newsletter@marketsandmarkets.com

Mr. Shelly Singh

MarketsandMarkets™ INC.

630 Dundee Road

Suite 430

Northbrook, IL 60062

USA : 1-888-600-6441

newsletter@marketsandmarkets.com

No comments:

Post a Comment