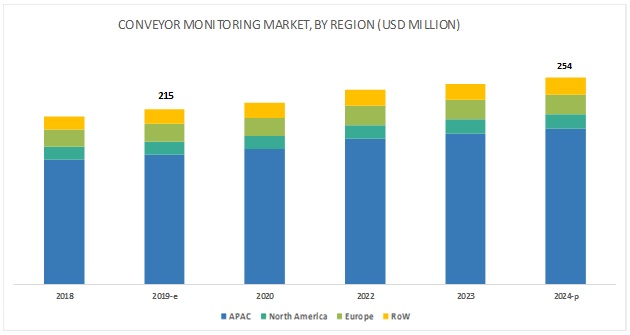

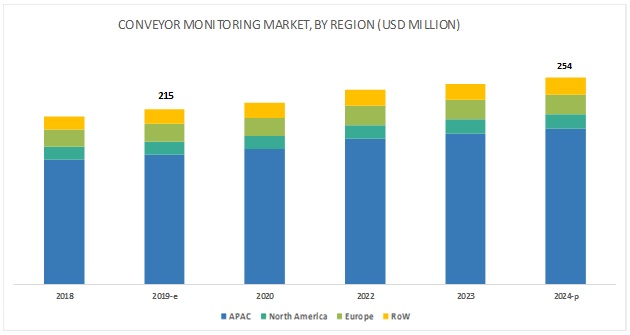

According to the new market research report "Conveyor Monitoring Market by (Technology, Offering, Deployment Type), Conveyor Belt Monitoring, Industry (Mining, Power Generation), and Geography (North America, Europe, APAC, RoW) - Global Forecast to 2024"The conveyor monitoring market is likely to reach USD 254 million by 2024 from USD 215 million in 2019; it is estimated to record a CAGR of 3.5%. The growth of this market can be attributed to the increasing focus of companies on reducing revenue loss due to faults in conveyor belts and motors, and the rising adoption of predictive maintenance tools and techniques .

• Download Informational PDF Brochure :- https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=55899833

Browse 32 market data Tables and 29 Figures spread through 100 Pages and in-depth TOC on "Conveyor Monitoring Market - Global Forecast to 2024"

“Conveyor belt monitoring to account for larger market share than conveyor motor monitoring”

Conventional methods of detecting failures in conveyors are unreliable, time-consuming, and labor-intensive. Conveyor belts carry tonnes of raw materials, minerals, and processed and unprocessed goods from a great distance. Conveyor belts are subject to many problems, including longitudinal cracks, damages to belt edges, belt wear and tear, belt overlapping on pulleys, cord misalignment, and insufficient belt cleaning. The productivity of companies carrying out mining activities or generating power is directly proportional to the continuous availability of conveyor belts. Monitoring the conveyor belt helps avoid costly shutdowns by timely inspecting defects and raising the precautionary alarm in such cases.

“Mining industries to lead conveyor monitoring market from 2019 to 2024”

Conveyor monitoring becomes crucial for processes involved in mining. Mining sites are usually remotely located with the possibilities of having hazardous or inaccessible locations. Conveyors are commonly used in carrying raw materials or minerals for processing. The productivity of mining sites depends on the continuity of the mining process, which, in turn, directly depends on the availability of continuously working conveyors. To ensure the continuous work of conveyors, it is essential to monitor the health of the conveyor belts and conveyor motors. Conveyor monitoring equipment not only monitor the health of conveyors but also predict any potential damages or downtime so that actions can be taken beforehand. Also, conveyor monitoring ensures the safety of miners as transporting minerals from hazardous locations may prove injurious or fatal.

“APAC to be largest market for conveyor monitoring during forecast period”

APAC is anticipated to be the fastest-growing region for the conveyor monitoring market due to the technological innovation and adoption of automation technologies in various industries. The APAC region is witnessing a surge in the deployment of conveyor monitoring solutions. China and Australia, being the top mining countries, have been adopting real-time conveyor monitoring systems to increase the operational efficiency and production in the country. Conveyor monitoring solutions help miners to optimize their operating costs by predicting failure of conveyors to achieve high efficiency in production. Australia has the highest number of mining sites and activities. Mining sites in Australia have focused on mining automation that includes the use of conveyor monitoring solutions in those mining sites. Major Australian players such as Fenner Dunlop and Beltscan offer a wide range of products in conveyor monitoring. With Australia being the forerunner in the mining industry, the APAC region holds the largest market share of the conveyor monitoring market.

• Ask for Sample Pages of Report :- https://www.marketsandmarkets.com/requestsampleNew.asp?id=55899833

Beltscan Systems Pty Ltd. (Australia), Yellowtec (Australia), Honeywell International Inc. (US), ContiTech Conveyor Belt Group (Germany), Fenner Dunlop (Australia), PHOENIX CBS GMBH (Germany), Emerson Electric Co. (US), Bruel & Kjaer (Denmark), SKF (Sweden), and Parker Hannifin Corporation (US) are a few major players operating in the conveyor monitoring market.

About MarketsandMarkets™

MarketsandMarkets™ provides quantified B2B research on 30,000 high growth niche opportunities/threats which will impact 70% to 80% of worldwide companies’ revenues. Currently servicing 7500 customers worldwide including 80% of global Fortune 1000 companies as clients. Almost 75,000 top officers across eight industries worldwide approach MarketsandMarkets™ for their painpoints around revenues decisions.

Our 850 fulltime analyst and SMEs at MarketsandMarkets™ are tracking global high growth markets following the "Growth Engagement Model – GEM". The GEM aims at proactive collaboration with the clients to identify new opportunities, identify most important customers, write "Attack, avoid and defend" strategies, identify sources of incremental revenues for both the company and its competitors. MarketsandMarkets™ now coming up with 1,500 MicroQuadrants (Positioning top players across leaders, emerging companies, innovators, strategic players) annually in high growth emerging segments. MarketsandMarkets™ is determined to benefit more than 10,000 companies this year for their revenue planning and help them take their innovations/disruptions early to the market by providing them research ahead of the curve.

MarketsandMarkets’s flagship competitive intelligence and market research platform, "Knowledgestore" connects over 200,000 markets and entire value chains for deeper understanding of the unmet insights along with market sizing and forecasts of niche markets.

Contact:

Mr. Shelly Singh

MarketsandMarkets™ INC.

630 Dundee Road

Suite 430

Northbrook, IL 60062

USA : 1-888-600-6441

newsletter@marketsandmarkets.com

• Download Informational PDF Brochure :- https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=55899833

Browse 32 market data Tables and 29 Figures spread through 100 Pages and in-depth TOC on "Conveyor Monitoring Market - Global Forecast to 2024"

“Conveyor belt monitoring to account for larger market share than conveyor motor monitoring”

Conventional methods of detecting failures in conveyors are unreliable, time-consuming, and labor-intensive. Conveyor belts carry tonnes of raw materials, minerals, and processed and unprocessed goods from a great distance. Conveyor belts are subject to many problems, including longitudinal cracks, damages to belt edges, belt wear and tear, belt overlapping on pulleys, cord misalignment, and insufficient belt cleaning. The productivity of companies carrying out mining activities or generating power is directly proportional to the continuous availability of conveyor belts. Monitoring the conveyor belt helps avoid costly shutdowns by timely inspecting defects and raising the precautionary alarm in such cases.

“Mining industries to lead conveyor monitoring market from 2019 to 2024”

Conveyor monitoring becomes crucial for processes involved in mining. Mining sites are usually remotely located with the possibilities of having hazardous or inaccessible locations. Conveyors are commonly used in carrying raw materials or minerals for processing. The productivity of mining sites depends on the continuity of the mining process, which, in turn, directly depends on the availability of continuously working conveyors. To ensure the continuous work of conveyors, it is essential to monitor the health of the conveyor belts and conveyor motors. Conveyor monitoring equipment not only monitor the health of conveyors but also predict any potential damages or downtime so that actions can be taken beforehand. Also, conveyor monitoring ensures the safety of miners as transporting minerals from hazardous locations may prove injurious or fatal.

“APAC to be largest market for conveyor monitoring during forecast period”

APAC is anticipated to be the fastest-growing region for the conveyor monitoring market due to the technological innovation and adoption of automation technologies in various industries. The APAC region is witnessing a surge in the deployment of conveyor monitoring solutions. China and Australia, being the top mining countries, have been adopting real-time conveyor monitoring systems to increase the operational efficiency and production in the country. Conveyor monitoring solutions help miners to optimize their operating costs by predicting failure of conveyors to achieve high efficiency in production. Australia has the highest number of mining sites and activities. Mining sites in Australia have focused on mining automation that includes the use of conveyor monitoring solutions in those mining sites. Major Australian players such as Fenner Dunlop and Beltscan offer a wide range of products in conveyor monitoring. With Australia being the forerunner in the mining industry, the APAC region holds the largest market share of the conveyor monitoring market.

• Ask for Sample Pages of Report :- https://www.marketsandmarkets.com/requestsampleNew.asp?id=55899833

Beltscan Systems Pty Ltd. (Australia), Yellowtec (Australia), Honeywell International Inc. (US), ContiTech Conveyor Belt Group (Germany), Fenner Dunlop (Australia), PHOENIX CBS GMBH (Germany), Emerson Electric Co. (US), Bruel & Kjaer (Denmark), SKF (Sweden), and Parker Hannifin Corporation (US) are a few major players operating in the conveyor monitoring market.

About MarketsandMarkets™

MarketsandMarkets™ provides quantified B2B research on 30,000 high growth niche opportunities/threats which will impact 70% to 80% of worldwide companies’ revenues. Currently servicing 7500 customers worldwide including 80% of global Fortune 1000 companies as clients. Almost 75,000 top officers across eight industries worldwide approach MarketsandMarkets™ for their painpoints around revenues decisions.

Our 850 fulltime analyst and SMEs at MarketsandMarkets™ are tracking global high growth markets following the "Growth Engagement Model – GEM". The GEM aims at proactive collaboration with the clients to identify new opportunities, identify most important customers, write "Attack, avoid and defend" strategies, identify sources of incremental revenues for both the company and its competitors. MarketsandMarkets™ now coming up with 1,500 MicroQuadrants (Positioning top players across leaders, emerging companies, innovators, strategic players) annually in high growth emerging segments. MarketsandMarkets™ is determined to benefit more than 10,000 companies this year for their revenue planning and help them take their innovations/disruptions early to the market by providing them research ahead of the curve.

MarketsandMarkets’s flagship competitive intelligence and market research platform, "Knowledgestore" connects over 200,000 markets and entire value chains for deeper understanding of the unmet insights along with market sizing and forecasts of niche markets.

Contact:

Mr. Shelly Singh

MarketsandMarkets™ INC.

630 Dundee Road

Suite 430

Northbrook, IL 60062

USA : 1-888-600-6441

newsletter@marketsandmarkets.com